May, 2021

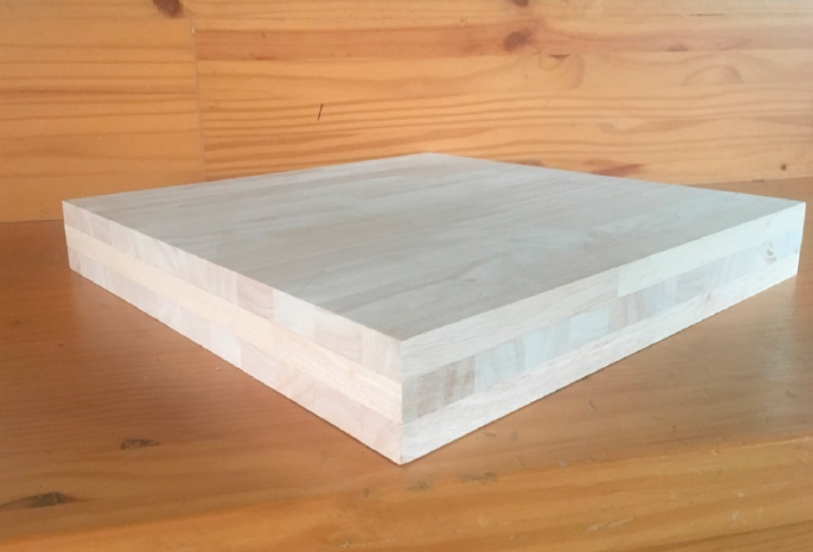

Effects of manufacturing parameters on properties of rubber wood – cross laminated timber manufactured via hot pressing

Suthon Srivaro, Satjapan Leelatanon, Monthian Setkit, Nirundorn Matan, Sureurg Khongtong, Sataporn Jantawee, and Jaipet Tomad

Abstract:

In this study, cross-laminated timber (CLT) was manufactured from rubberwood via hot pressing. The effects of manufacturing parameters, such as resin content and clamping pressure, on the following properties of CLT panels were investigated: density (ρ), water absorption (WA), thickness swelling (TS), bonding strength (BS), compressive strength in the major strength direction of CLT (major), compressive strength in the direction perpendicular to the flat plane of CLT (flat)), and rolling shear strength (RS). The relationships among the properties of the CLT panel, those the original rubberwood material, and the manufacturing parameters was also explored. The results showed that the resin content and clamping pressure did not significantly affect most of the examined properties of the CLT panels. The ρ, WA, major, Flat, and RS of the panels could be estimated directly from the properties of the original rubberwood, while the TS could be estimated directly from the clamping pressure applied on the panel. However, no such relationship was found for the BS value. Compared with typical softwood-CLT, the rubberwood-CLT exhibited superior mechanical properties. This implies that CLT made of rubberwood can achieve better structural performance than standard CLT can.